Initiatives for the future

Introducing FES Inc.’s initiatives for the future.

- Utilization of CNF (cellulose nanofiber)

-

- Development of high-strength resin additives for material reduction toward SDGs sustainable society

-

- About the required material CNF

-

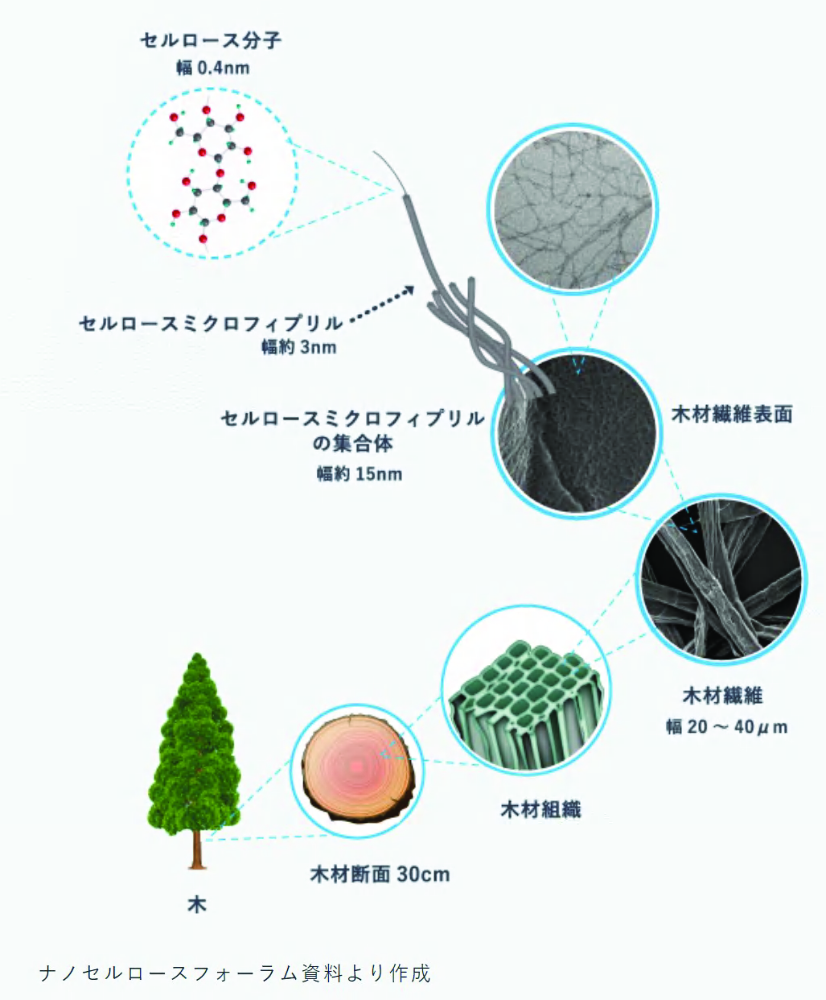

Cellulose nanofiber (CNF) is a fibrous material made by disentangling cellulose, the main component of wood and other plants, to a diameter of several to several tens of nanometers (1 nanometer = 1 billionth of a meter).

Cellulose nanofibers made from plants are known to have a low environmental impact and have various excellent properties.

The width of this minimum unit fiber material “cellulose microfibril” is 3-4 nanometers, and the specific gravity is one-fifth that of steel (1.5 grams per cubic centimeter). It can secure bending strength and tensile strength five times.Thermal deformation is as small as quartz glass, and it is resistant to temperature changes.It also has gas barrier performance that makes it difficult for gases such as oxygen to pass through.

In fact, it is expected to be used for a wide range of purposes, and paper manufacturers are currently research and development and application development are underway in a variety of industries, including the industry, but the current difficulty in manufacturing and high prices are hindering their widespread use. - Aiming to halve the material by adding a small amount

-

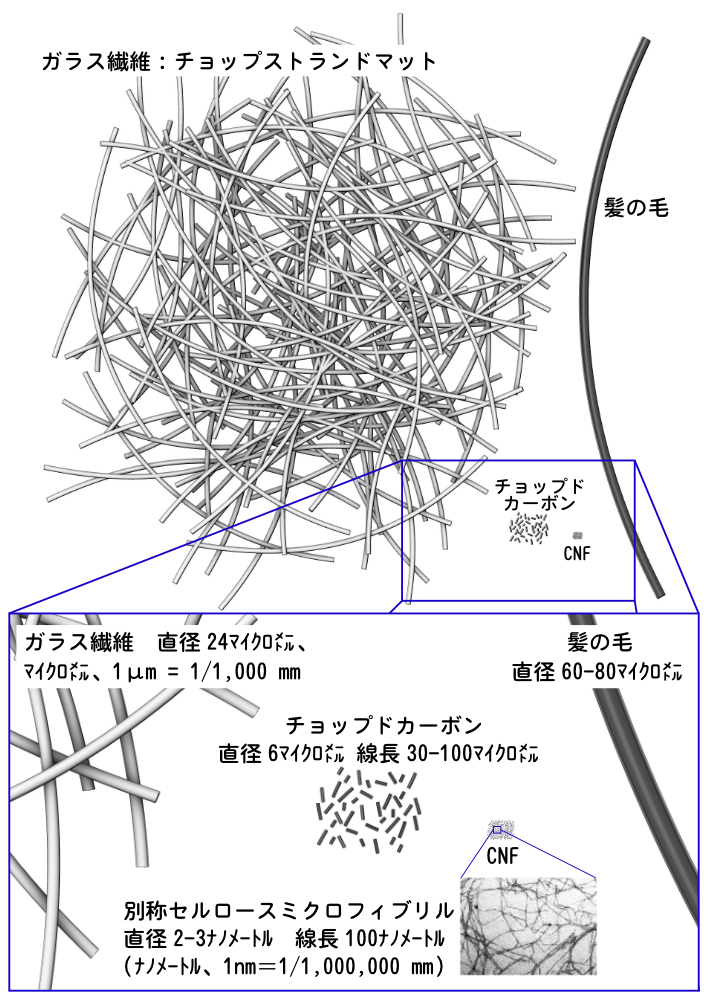

By neatly dispersing the chains of a molecule called CNF, unexpected performance is achieved. However, because it is so thin, it is difficult to halve the amount of physical glass fiber backup using the hand layup method we have been using. Therefore, short carbon fibers are blended with CNF-dispersed resin and impregnated into glass fibers. It is necessary to consider this material distribution.

By combining three materials with different thicknesses used as industry standards: long fibers of glass fibers, short fibers made from crushed recycled carbon, and fine fibers that have been reduced to the size of molecules, we have created an unprecedented product. Strong expression is predicted. Accelerate the dispersal of the optimal amount of ingredients and testing, and establish a system for stable supply.

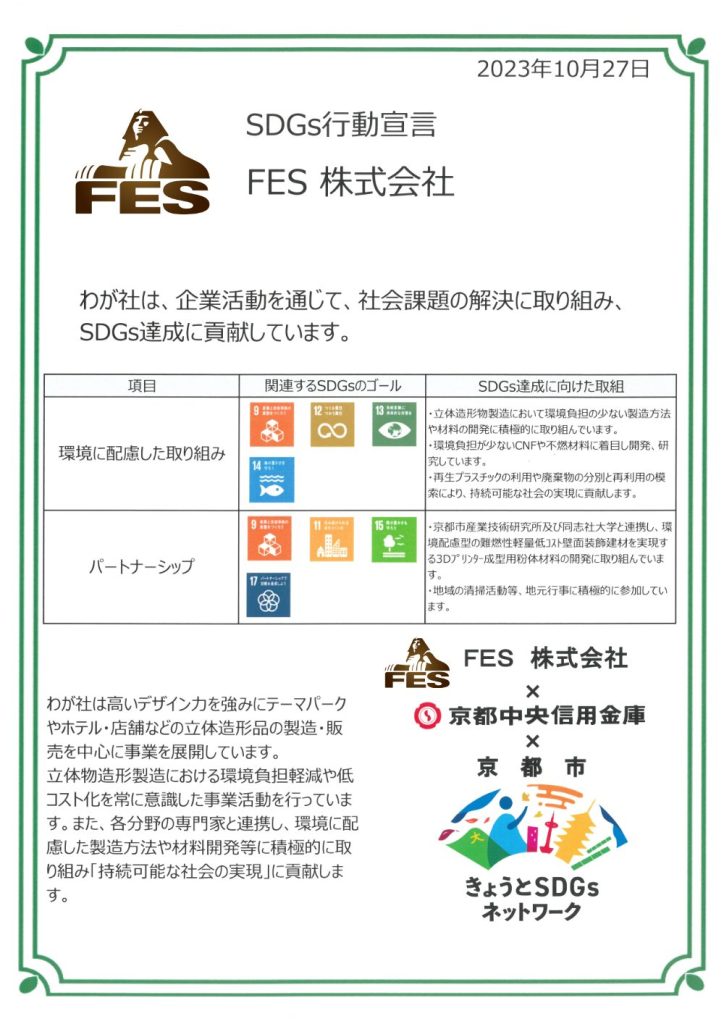

- SGDs

- Exploring the separation and reuse of recyclable materials (biodegradable plastics) and waste as a sustainable initiative.

-

Kyoto City has established the “Kyoto SGDs Network” as a mechanism for the public and private sectors to work together to support businesses that actively work to promote SDGs and solve local issues, in collaboration with financial institutions and related organizations. Ta.

- AI Python

- Determining the difficulty of production using image recognition deep learning and increasing the accuracy of estimates by centralizing cost calculations.

- CNF

- Making FRP lighter and stronger using cellulose nanofibers.

- Incombustible

- Exploring and studying to create products that are safe for the environment and fires by using noncombustible materials.

- Air

- Developing an air purifier as one of our efforts to combat the COVID-19 pandemic.