An express project from a customer who has been requested several times before.

Using a vacuum forming machine inherited from a company that is going out of business, I was asked to make an original mask.

-

-

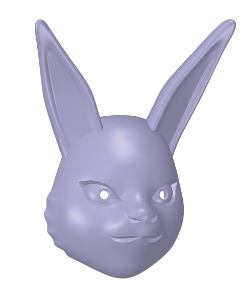

- A. 3D data production

-

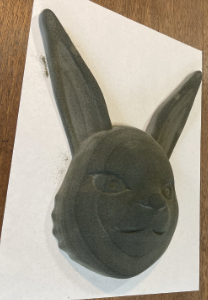

- B. Sand print male mold

-

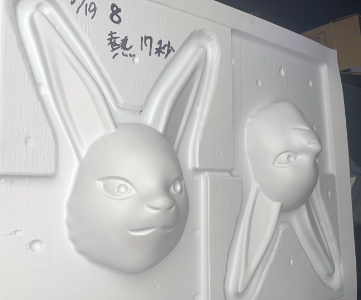

- C. Vacuum molding

-

- D. Thomson type mold

-

-

-

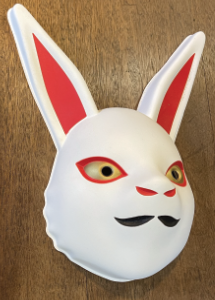

- E. Painting

-

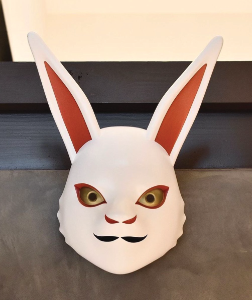

- F. Finished

-

- G. Resin printed product

-

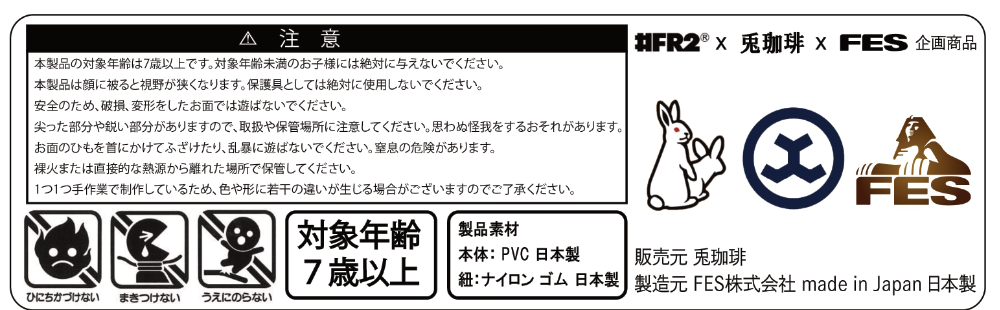

The location is in front of Nijo Castle in Kyoto. For the opening of the first restaurant handled by the fashion brand “#FR2”, we were asked to create a Kyoto version of the main character. First of all, after creating a resin print product (image G) and getting permission from the client for the shape, For the time being, we discussed and considered how many we could make in the month before the opening. However, we did not know how to use the vacuum forming machine in question, and it was not possible to form evenly. At first, we tried to mold it using a sheet with the pattern of the mask printed on it, but we gave up early on. If I could do this, I think I would have been able to make a lot more cheaply. Also, around the same time that we received this project, we were conducting operational testing of a sand printer that had just been introduced in-house. Since the sandprint product is porous, I experimented to see if it could be used as a male prototype for vacuum molding, and was able to use it successfully. Discovering new uses for sand-printed products like this is a happy secondary by-product for us. In the end, the unit price per piece was surprisingly high due to the ultra-small production of 50 pieces. However, our products were able to play a role in creating an atmosphere at the time of the opening, such as the staff hanging the masks diagonally on their heads like they were at a festival.

https://www.instagram.com/_usagicoffee/