Through an introduction from a senior colleague, We had the opportunity to help with the store decorations produced by artist Sebastian Masuda.

We have also had experiences in the past where products we exhibited in Japan were taken overseas. In many cases, it is not acceptable to disclose such information on websites, etc., but this time we will introduce it with the consent of the artist himself.

For projects that cannot be published on the website, you can view them by contacting us. Please feel free to contact us.

The location is New York, so far away that you can’t say, “I’m going to go do some repairs.” This was the first time for us to have a project that was unveiled overseas from the beginning.

We made light fixtures in the shape of three cats and lipstick that hang from the ceiling.

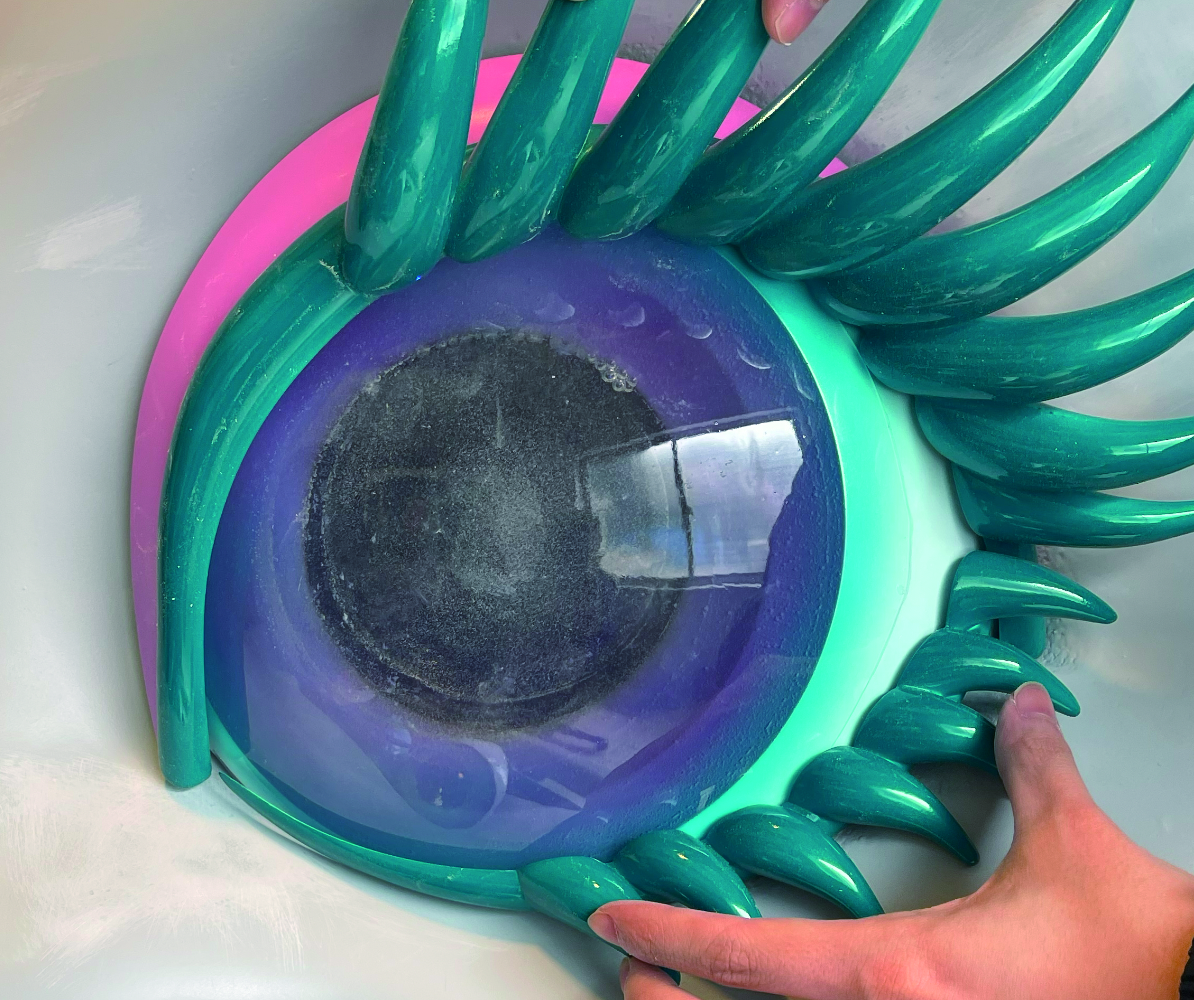

The three cats are designed to rotate slowly, and the back of each cat’s face is made up of sushi ingredients or lips, and we were first shown some of their bizarre designs. The overall color scheme was pastel, with green sauce on the tuna and sushi rice painted in blue and pink, which overturned our common sense.

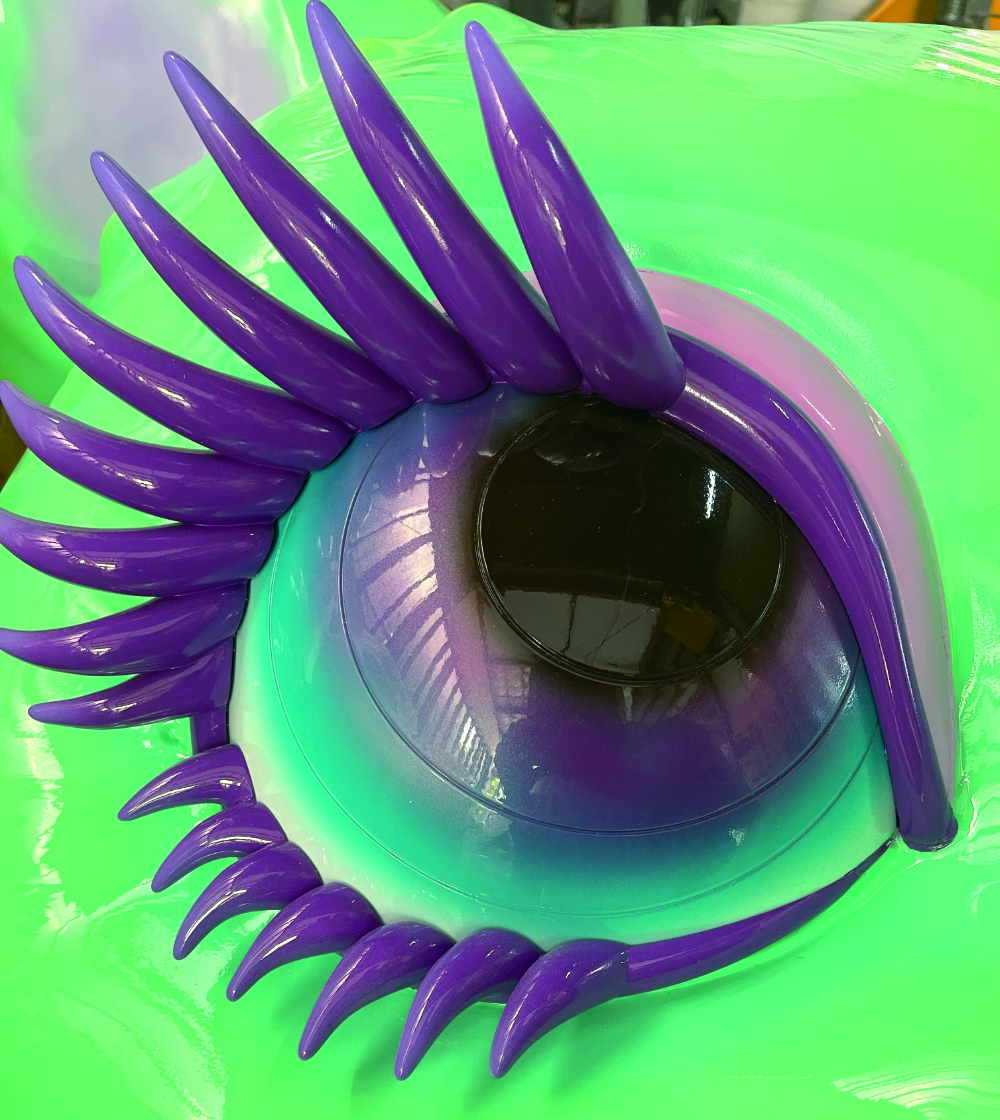

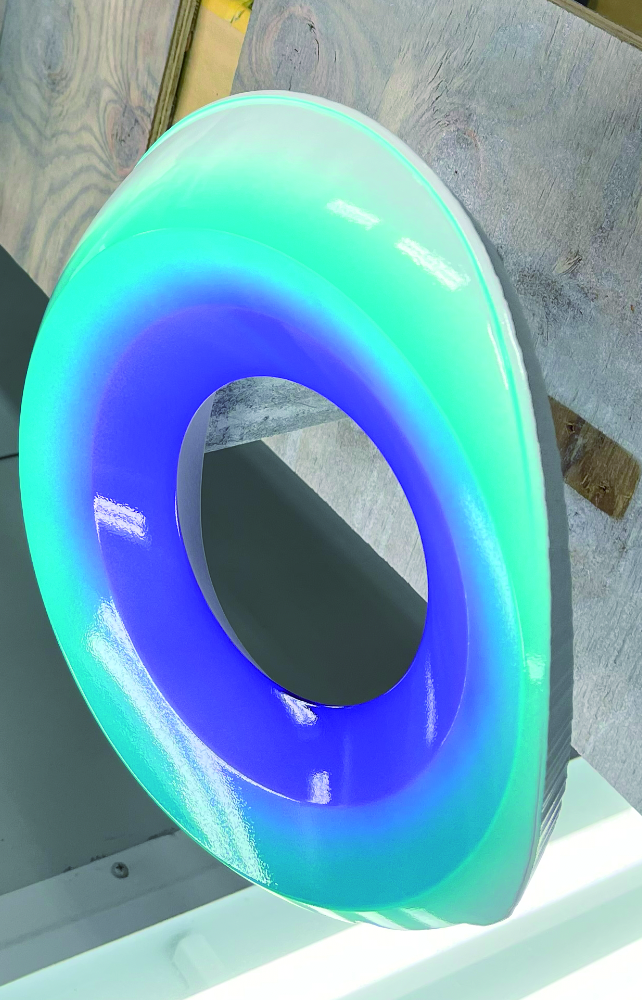

Mr. Sebastian, who travels between New York and Japan, came to our company in the mountains of Kyoto many times and we had detailed discussions with him. While listening to the story, we felt that this story is a commercial three-dimensional object, but it is a work that oozes out the artist’s personality, and we thought that in order to express it, we needed some ingenuity. We set the important point was the “cat’s eyes” drawn with a mysterious touch. Therefore, we created a sample of the pupil with a concave shape and poured epoxy resin into it, as well as a few samples of the eyes made using the normal method, and showed them to the artist for consideration. In the end, we chose an internal illumination method in which a film depicting the universe is placed behind the eyes and illuminated from within.

The large lipstick, which is about 50 centimeters in height, needed to be made into a lighting fixture that could actually be hung from the ceiling, so we initially thought of creating one master prototype and making molds and FRP molding. However, consideration must be given to ease of maintenance, including replacement in the event of a malfunction of the internal lighting, how to fix the surrounding diamond decorations, the angle of entry for each color of the product, masking work when painting separately, and deformation of the final product due to temperature, etc. I redesigned the lip again. In the end, we decided to use transparent FRP for the tip, PVC pipe for the cylinder, and 3D printing for the ring. It’s hard to tell from the photo, but thanks to the paint I used for the first time (mirror paint from Origin Co., Ltd.), We were able to achieve a very high-class finish.

Although this project was a first for us, we were very happy to hear that there was a waiting list of 3,000 people for reservations at the store in New York.